The Challenge

Managing the movement and maintenance of Lifting Gear - which includes heavy equipment, such as slings, chains and wire ropes, presents some particular challenges. But the rewards for installing an effective, easy to use, and accurate system are significant. The main challenge is in identification. Lifting gear is often used in environments which are hostile to many auto-id solutions. Equipment may be covered in oil or grease, and may be painted as it is maintained. The working and transport environments can be hostile, with much heavy equipment being transported by truck. The materials themselves are heavy and robust. They don't demand care and don't receive it, so the marking system must match that robustnes. Equipment may spend time outside in low or high temperatures, and exposed to the elements, ice and rain.

The Solution

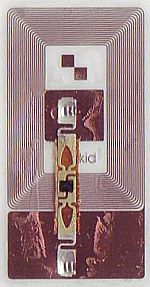

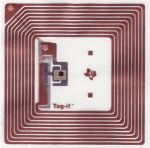

Barcode technology is generally the first stop when considering a tracking problem. In this case, when lifting gear, which includes heavy slings, chains and wire ropes, it can be ruled out quickly. Even metal tags (usually aluminium) are not sufficiently robust, and cannot be painted over. That leaves RFID, but even RFID tags are not natively robust enough for this environment. The effects of the metal on the items to be tracked can also present problems. The ideal tag would be robust enough to be dropped, and to have heavy equipment dropped on it. It would be readable even when painted or covered in grease.

The best solution for tracking lifting gear is to use passive UHF RFID tags mounted in a steel protective shell. Of course the shell must be designed in such a way that the RFID tag can still be read. The trade off here is between range and robustness. A laundry style tag is used, which has limited range to start with, and the effect of the metal shroud is to reduce that range still further. It effect, the tag becomes almost a contact tag, but in the context in which it is used, that does not present a real drawback.

Reading and Writing

This is done using a handheld computer with built in RFID reader. The recommended model is the Workabout Pro from Psion Teklogix. The handheld computer is running BassetPro mobile, which gives the ability to set up new items, to track action required for a given item, and to capture information relating to testing, including identity of the tester, date and time of the test, and further details. A signature can be captured on the handheld computer, and passed back to the desktop element of the system, so that test certification forms can be produced in hard copy, complete with the testers signature.

Other Features

This note addresses issues specific to this application. The full range of features of BassetPro is available, including tracking of assets from receipt to disposal, and reporting on all movements and maintenance activities. There is no effective limit to the number of items that can be tracked. The system can be configured to your specific requirements, including information to be captured for each asset, and the format of the reports and certification forms.

Benefits

The system ensures that items can be identified easily, quickly and accurately. Movements can be tracked. Because the recording process is so quick, it is possible in a real world situation to record all movements, which can help reduce equipment losses, and enables equipment to be located quickly when needed. The tracking of maintenance activities helps ensure that maintenance is carried out on time, as well as helping to ensure compliance with all health and safety rules.

Questions?

Call Doreen Wallace or Trinity Joseph at 613 225 4404, or email to info@sagedata.com

To reach us by phone from Ottawa, dial 613 225 4404

To reach us by phone from outside Ottawa, dial 1-888-838-1067

© SageData . Ottawa . Ontario . Canada

QAP