Introduction

In this section of the site we describe some of the challenges around various situations, and provide examples of how they can be managed. The examples given are based on our own experiences with real life applications.

The Situation.

You are responsible for a small warehouse or large stores. The company is small, less than one hundred employees. The stores / warehouse has gradually expanded over time. Old George has been running it for the last fifteen years, and has just retired. He knew pretty much where everything was, and didn't have much time for computers. The stores is run on a combination of paper records and a huge spreadsheet, which has itself grown over time. There is only one person who knows how to use the spreadsheet. You have been having several problems. Parts are missing, or not available when required by manufacturing. You have had several shipments stuck at the border because the paperwork was incorrect. This despite an average of two days that it takes to prepare the customs paperwork. (Note: This is a real life situation, and actually a combination of two very similar clients.)

First Steps

One of the first steps is to review the stores, to determine how organised the inventory is. Not matter how good a software system, it can't overcome the problems of disorganisation. So proper shelves, proper labeling, and nothing on the floor unless it is too big to go on a shelf. And no dead stock (though the system can be used to identify that later.) Putting smart software on top of a scruffy stores is a bit like putting lipstick on a pig.

Data In

In most small stores information is passed from another system, perhaps a financial system that controls the purchasing. This is sometimes passed directly, more often through a spreadsheet. The spreadsheet can also originate with the design or manufacturing group, who originally placed the (internal) order for the parts. Provided that the key information is available, it is usually fairly easy to provide an interface to import this information into the Warehouse Management System (WMS).

Material flow

For all its complexity, any WMS can be reduced to four basic steps,with some add-ons. The four basic steps are receive, put-away, pick and ship. Add-ons might include audit and dispose.

Receive

The data transfer will have passed key information to the WMS enabling the shipment being received to be identified. Typically, this will be by PO number and line number. Receipt is done with a handheld computer. The user logs on with name and password (so that all actions can be tracked). They then enter PO number and line number, and enter quantity. Depending on the level of the system, it may either check against expected quantities, or may accept blind. As most inventory is tracked by SKU (as distinct from UIC, or item level tracking), demand printing is employed to provide appropriate labels, which include a barcode identifier. Unique SKU may already exist, but can be generated by the WMS.

Put-away

As material has already been marked with a barcoded identifier the put away process is easy, fast and accurate. This of course assumes that all locations have been identified (eith barcoded labels) as part of the set up process. Again the Handheld Computer (HHC) is used, and the process is as simple as scanning the location, scanning the SKU on the item, and entering the quantity to be stored at that location.)

Pick

Usually the pick order will have been generated by an external system, and the information imported to the system. As an alternative, the WMS can be used to enter data, and this can even be extended to enable orders to be placed via a web page. This has the effect of "outsourcing" the order entry process, and can give a significant reducion in ship errors. If the system is large enough, the supervisor has the option to allocate specific tasks to particular individuals. The users logs on, and are presented with a list of pick orders. They select an order, and are instructed to pick, being given the location, the item to be picked, and quantity required. Because each items is scanned as it is picked, any pick errors are immediately detected and can be corrected. When all items have been picked, the system confirms same, and the operator has the option to move on to the next order. The system can automatically print a packing list which shows items picked (which may differ from items ordered)

Ship

This is a simple process. It is included because in some cases there can be a delay between pick and ship. The user selects the ship function, and scans the barcode printed on the packing list.

Data Transfer

Data collected during receiving, picking and shipping is made available in a standard format, but can be presented in a format to match the client's back end system. This enables the key information to be passed to the back end system to authorise payment or confirm shipments.

Reporting

The WMS includes comprehensive reporting features, including canned reports, ad hoc reporting (by means of a reporting wizard), and a "mindless dump" that provides a complete set of raw information for further processing by third party applications.

Conclusion

The above brief description is intended to provide an introductory overview for those not already familiar with these systems. We are of course happy to answer any questions you may have about a specific application that you may be considering.

For more information...

SageData is based in Ottawa, Ontario, Canada.

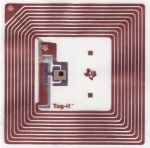

We design systems around RFID, Barcodes and Handheld computers.

For further information, contact Doreen Wallace or Keith Jackson.

To reach us by email, click here.

To reach us by phone from Ottawa, dial 613 225 4404

To reach us by phone from outside Ottawa, dial 1-888-838-1067

SageData . Ottawa . Ontario . Canada

QAP