Introduction

You may be wondering if your application is a suitable candidate for a Material Management System. Probably. In this section we give examples of assets and inventory that we have configured systems for. We have included examples in many cases.

IT Equipment

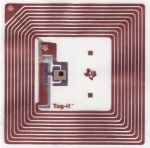

Probably our most common application. Used to track not only System Units, Monitors and Printers, but also network equipment and other related IT assets. Barcodes are most often used for identifying specific items, but in a few cases RFID has been deployed. Handheld computers are typically used to collect data. These are UIC systems, with item level tracking. Each piece is individually tracked. Benefits are fiscal compliance, maintenance tracking, compliance with end of lease requirements, safety issues (such as tracking who is to be advised of potential exploding batteries.)

Warehouses

Generally use multiple handheld computers linked using wireless. Most often sku based, but can be UIC based for high value items. Most follow a standard pattern of Receipt, Put-away, Pick and Ship. Benefits may include faster turnaround, more accurate inventory counts, more flexibility in storage.

Inspections

Most usually for UIC based systems. Can be used to collect information for legacy systems, or to record inspections. Can provide a check list for inspectors. Can provide a route to be followed. Auto ID usually barcode but RFID is possible in some circumstances. Benefits include proof of compliance, and timely access to data. Examples include HVAC equipment, safety equipment.

Maintenance

UIC systems only. Can be used for scheduled and unscheduled maintenance. Can be used to track costs and response times. Can also capture use of consumables. Proof of compliance for systems have an impact on health and safety.

Stores

SKU based systems can be used to track receipt and issues of pens and pencils, chemicals, maintenance materials, weapons, radios and vehicles. Benefits include fast processing, and tight tracking of responsibility.

Safety Equipment

Items are individually tracked, and inspected on a regular basis. Fire prevention equipment is a common use. Quote from a client - "I always knew everything was inspected. But now I can prove it."

Food Safety

A specialised version of the inspection process, can be used to confirm temperatures of refrigerators and freezers. RFID tags can be used to identify the unit being tested and to measure current temperature. The system can also be used for routine checks to make sure that all food safety rules are being followed.

Test Equipment

Used in production, development or research labs, modern test equipment can be expensive. Most requires calibration, and failure to follow the calibration procedures can mean loss of certification. A material management system can track the current location of each piece of equipment, as well as its operational status and calibration status. Barcode tags can be used, but in some cases RFID is used, active or passive. Active tags are more expensive than passive or barcode, but as one client explained "the test boxes cost about $100,000 each, so $40 for an active RFID tag is not really an issue, especially when it helps safeguard our certification."

For more information...

SageData is based in Ottawa, Ontario, Canada.

We design systems around RFID, Barcodes and Handheld computers.

For further information, contact Doreen Wallace or Keith Jackson.

To reach us by email, click here.

To reach us by phone from Ottawa, dial 613 225 4404

To reach us by phone from outside Ottawa, dial 1-888-838-1067

SageData . Ottawa . Ontario . Canada

QAP