Introduction

Our mission at SageData is to help our clients manage their stuff - from fixed assets to consumables. In this section we talk about the tools we have developed, and how they can improve the efficiency of your operations, improve service to your clients, and reduce your workload. It is all about improving the service to your clients (external or internal), and reducing the cost of operations.

What tools do we offer?

Any material management operation can be considered to have two elements - data collection and reporting. Under data collection we need to identify the materials being processed, and we nned to do that quickly and accurately. We need to capture critical information, store it securely, process it intelligently, keep it safe, and make it available to all those who have a need to know, and make sure it is not available to anyone else. Identification of the material is usually done by an auto ID process, which usually means barcode technology or RFID (Radio Frequency Identification). Data must be collected quickly and accurately, which means by direct entry to computer, and this usually means that the computer must be taken to the work, which introduces handheld computer (HHC). The following sections provide more detailed information. In the following text we have tried to share many of the ideas we have picked up over twenty years of "hands on" experience with these systems.

Barcode Technology

An established technology which is simple, reliable and inexpensive. Although rival RFID is a better solution for specific tasks, barcode technology is still the leading candidate for most solutions. For asset tracking, where items are tracked individually, pre-printed labels usually provide the best solution. For SKU based tracked, where many items share a common identification number, demand printing is usually required. Caution, because of their mechanical construction, printers are often one of the least reliable elements of a system. Where possible, demand printing should be avoided, and pre-printed labels used to identify materials being tracked. There is much confusion over the different types of barcode symbology available (Codes 128, 39, two of five, EAN, and now QR Codes). The short answer is that Code 128 (and preferably 128C) usually the best solution, but contact us for more advice about your particular application.

Barcodes can be read by fixed readers, by cordless (or corded)readers attached to a workstation, or by an integrated reader in a mobile handheld computer. This later configuration is generally preferred as providing most flexibility, with the added benefits or reliability and maintainability.

Generally, barcodes provide a good solution for identifying specific materials and recording actions against them. SageData have a deep understanding of this technology. We can review your requirements, advise on the best solution, provide the hardware, software and stock for printing labels, and advise on best format, materials, adhesives etc. Contact Trinity Joseph or Doreen Wallace for further information.

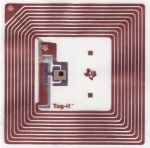

Radio Frequency Identification - RFID

This technology uses a small chip to transmit a short range radio signal with a unique identification code, enabling the identification of the chip, the tag, and by association any attached materials. Line of site is not required, so tags can be read inside a (cardboard)box, and many tags can be read at a given time. Readers can be continually monitoring for signals, so no specific action is required. Introduced from around 2005, RFID has failed to meet it's original expectations. It provides several interesting benefits, and that has lead to many unique solutions, but it should be seen as an alternative solution, not as a natural replacement for barcodes. More information is available elsewhere on this site with detailed information on the strengths and weaknesses of RFID

The hand held computer

Few organisations would employ and office worker without provided them with a dedicated computer. The benefits in improved efficiency are not questioned. We foresee a near future in which everyone working away from the desk will have their own mobile computer too. For material management the benefits are considerable. For a fixed asset audit, the handheld computer can confirm the location of an asset, as well as the time and date of audit, and the identity of the person conduting the audit. And it can do this in less than a second. In a warehouse or store environment the handheld computer can record receipts, put-away, pick, ship, issue, stock check and movement. And the information is secure, and can be passed on, immediately (with a wireless connection) or later (when other factors prohibit radio being used.) SageData provide hardware from the main manufacturers (Psion, Motorola (ex Symbol) and Intermec). We can review your application and advise the models and configuration most appropriate for your application.

For more information...

SageData is based in Ottawa, Ontario, Canada.

We design systems around RFID, Barcodes and Handheld computers.

For further information, contact Doreen Wallace or Keith Jackson.

To reach us by email, click here.

To reach us by phone from Ottawa, dial 613 225 4404

To reach us by phone from outside Ottawa, dial 1-888-838-1067

SageData . Ottawa . Ontario . Canada

QAP